For many years the uPVC window companies have been telling us that their windows are better than timber windows because they counteract the pitfalls of timber windows that we all remember from the 80s and 90s. They have been telling us now for years that uPVC windows have a long life, need no maintenance or redecoration, they are more energy-efficient, leave trees in our forests, can be recycled and are environmentally friendly and well we bought it, and as a result, many of our homes in the UK have uPVC windows now fitted.

Finding Proof

To prove, what we as wooden window manufacturers already knew, that these claims were misleading to say the least, Bereco and a number of other wooden window companies came together to form the Wood Window Alliance (WWA) in 2007.

In 2013 after many years of listening to the false claims of the uPVC window companies, the WWA approached Heriot Watt University to undertake a study our aim to prove once and for all by independent comparison of window frame material that gone are the wooden windows of the 80s and 90s, here is a new product one which is better than uPVC.

The study looked into the product design life of modern wood windows relative to building life expectancy; whole of life costs including initial product cost, installation, replacement and maintenance and investigated life cycle to determine the environmental impact of WWA member’s windows vs other window materials including that of uPVC.

The Proof is in the Product

The study determined that the manufacturing criteria pioneered by the WWA members play a very strong role in extending the service life of windows through the use of sustainable, defect-free, engineered timber, by the design of window elements such as rounded edges, water-shedding angles on cills and beads, and joint and end-grain sealing and also through the use of factory-applied microporous protective paint and factory controlled glazing systems.

One of the most important things we at Bereco feel to come out of the study is not only that things have changed and timber has a lower lifetime cost than uPVC, but it is also that for a 1.23m wide x 1.48m tall timber window a WWA endorsed timber window has global warming potential of -60kgCO2e per window.

The timber actually removes CO2 from our atmosphere and embodies and stores it in the wood. An equivalent uPVC window was found in the study to have a global warming potential of +100kgCO2e.

Counting Carbon

So following the logic to come out of the study for every 1.82m2 of timber window that Bereco manufacture the CO2e saving is 160kgCO2e because in buying a Bereco wooden window you have not bought a uPVC one and therefore have saved the 100kgCO2e that would have been put into the atmosphere and also saved 60kgCO2e in addition with the carbon sequestered by the timber.

The average size of a Bereco timber window or door is 2.88m² so a saving of 252kgCO2e is achieved by purchasing a Bereco timber window or door over a uPVC equivalent.

By following the findings from the study we have been able to determine that since starting our business Bereco have supplied over 261,000 wooden windows and doors which has saved over 66 million kgCO2e.

NB the calculations are based on the window assessed through the LCA analysis done by Heriott Watt which was 1.82m2. For the purposes of the counter the calculation shown on the Bereco homepage it is based on this independent evidence and then pro-rata by window area supplied by Bereco since 2003.

Putting it in Perspective

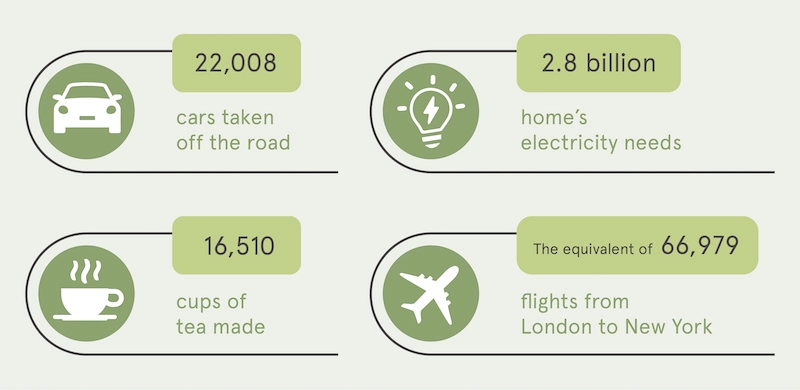

66 million kgCO2e is the equivalent of:

Assessing the Bereco Timber Sash Window

Not satisfied with stopping at just having this research we are pleased to announce that we are currently in the process of undertaking our first Environmental Product Declaration (EPD) on our sash window.

The British Wood Working Federation (BWF) have partnered with the BRE to be the first to use LINA tool. An online life cycle assessment tool (LCA) is capable of calculating the environmental impact of a product and then presenting the findings in the form of an Environmental Product Declaration or EPD.

Beatrix Richards, head of corporate stewardship (sustainable commodities) at WWF-UK speaking at the Ecobuild said;

“Tools exist to help architects, builders, suppliers and consumers to understand the true, full costs, from sourcing, manufacturing, transportation, lifetime use and disposal, so that decisions can be made on the best possible information. Life cycle assessments are one such way of capturing this information and WWF welcomes the British Woodworking Federation’s lead in adopting this approach.”

Look out for more in the coming months.